全部

▼

搜索

熱搜:

177

編輯:管理員

來源:苗琪,左孝青,周蕓,王應武,郭路,王坦,黃蓓

177

編輯:管理員

來源:苗琪,左孝青,周蕓,王應武,郭路,王坦,黃蓓

| Sample | Pore size/mm | Porosity/% | Fiber content/volume fraction, % | Fiber size/mm2 |

|---|---|---|---|---|

| 1# | 0.35+0.12 | 77 | 0 | … |

| 2# | 0.35+0.12 | 80 | 0 | … |

| 3# | 0.35+0.12 | 82 | 0 | … |

| 4# | 0.35+0.12 | 84 | 0 | … |

| 5# | 0.35+0.12 | 86 | 0 | … |

| 6# | 0.35+0.12 | 77 | 8 | ?0.1×5 |

| 7# | 0.35+0.12 | 80 | 8 | ?0.1×5 |

| 8# | 0.35+0.12 | 82 | 8 | ?0.1×5 |

| 9# | 0.35+0.12 | 84 | 8 | ?0.1×5 |

| 10# | 0.35+0.12 | 86 | 8 | ?0.1×5 |

| 11# | 0.35+0.12 | 82 | 2 | ?0.1×5 |

| 12# | 0.35+0.12 | 82 | 5 | ?0.1×5 |

| 13# | 0.35+0.12 | 82 | 11 | ?0.1×5 |

| Porosity/% | 77 | 80 | 82 | 84 | 86 |

|---|---|---|---|---|---|

| Alloy foam/MPa(1#~5#) | 1.90 | 1.30 | 0.80 | 0.70 | 0.50 |

| Composite foam/MPa(6#~10#) | 2.15 | 1.50 | 1.63 | 1.10 | 0.70 |

| Sample | 11# | 12# | 8# | 13# |

|---|---|---|---|---|

| Fiber content/% | 2 | 5 | 8 | 11 |

| Yield strength/MPa | 0.60 | 2.60 | 1.63 | 0.90 |

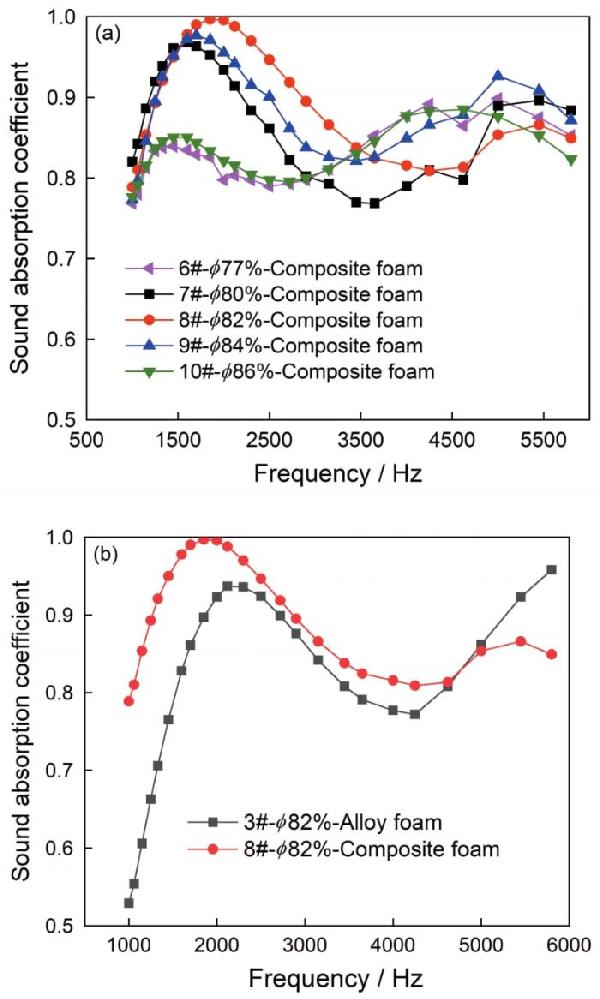

| Porosity/% | 77 | 80 | 82 | 84 | 86 |

|---|---|---|---|---|---|

| Alloy foam(1#~5#) | - | - | 0.810 | - | - |

| Composite foam(6#~10#) | 0.829 | 0.870 | 0.893 | 0.888 | 0.832 |

| Sample | 3# | 11# | 12# | 8# | 13# |

|---|---|---|---|---|---|

| Fiber content/% | 0 | 2 | 5 | 8 | 11 |

| Average sound absorption coefficient | 0.810 | 0.882 | 0.884 | 0.893 | 0.872 |

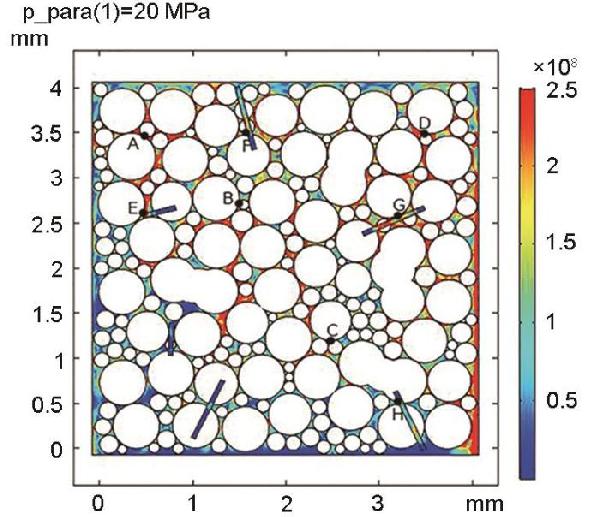

| Position | A | B | C | D | E | F | G | H |

|---|---|---|---|---|---|---|---|---|

| Stress /×109 Pa | 9.26 | 8.40 | 1.98 | 4.65 | 3.09 | 0.746 | 0.651 | 1.31 |

分享 0

分享 0

舉報 0

舉報 0

收藏 0

收藏 0

反對 0

反對 0

點贊 0

點贊 0