全部

▼

搜索

熱搜:

位置:中冶有色 >

> 焊后熱處理對(duì)7055-0.1Sc鋁合金攪拌摩擦焊接頭的組織與力學(xué)性能的影響

950

編輯:中冶有色技術(shù)網(wǎng)

來源:馬俊雅,張振,李靜靜,王貝貝,王英君,薛鵬,劉峰超,倪丁瑞,肖伯律,馬宗義

950

編輯:中冶有色技術(shù)網(wǎng)

來源:馬俊雅,張振,李靜靜,王貝貝,王英君,薛鵬,劉峰超,倪丁瑞,肖伯律,馬宗義

| Zn | Mg | Cu | Sc | Zr | Si | Fe | Mn | Al |

|---|---|---|---|---|---|---|---|---|

| 7.6~8.4 | 1.8~2.3 | 2.0~2.6 | 0.1 | 0.08~0.25 | ≤0.1 | ≤0.15 | ≤0.05 | Bal. |

| Yield Strength / MPa | Tensile Strength / MPa |

Elongation / % |

|---|---|---|

| 595±28 | 635±36 | 9±5 |

| Number | Sample | Tensile Strength / MPa | Elongation / % | Strength coefficient / % |

|---|---|---|---|---|

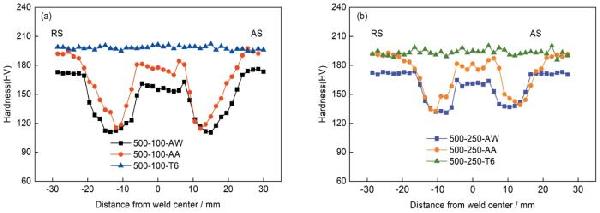

| 1 | 500-100-AW | 399.9±1.4 | 8.9±0.5 | 63.0% |

| 2 | 500-250-AW | 468.5±7.8 | 6.3±0.5 | 73.8% |

| 3 | 500-100-AA | 415.8±2.1 | 4.3±0.4 | 65.5% |

| 4 | 500-250-AA | 477.6±3.5 | 3.8±0.4 | 75.2% |

| 5 | 500-100-T6 | 556.5±1.5 | Brittle fracture | 87.6% |

| 6 | 500-250-T6 | 555.0±2.0 | Brittle fracture | 87.4% |

分享 0

分享 0

舉報(bào) 0

舉報(bào) 0

收藏 0

收藏 0

反對(duì) 0

反對(duì) 0

點(diǎn)贊 0

點(diǎn)贊 0

中冶有色技術(shù)平臺(tái)

中冶有色技術(shù)平臺(tái) 2024年12月27日 ~ 29日

2024年12月27日 ~ 29日  2025年01月03日 ~ 05日

2025年01月03日 ~ 05日  2025年01月03日 ~ 05日

2025年01月03日 ~ 05日  2025年03月25日 ~ 27日

2025年03月25日 ~ 27日  2025年04月27日 ~ 29日

2025年04月27日 ~ 29日