全部

▼

搜索

熱搜:

位置:中冶有色 >

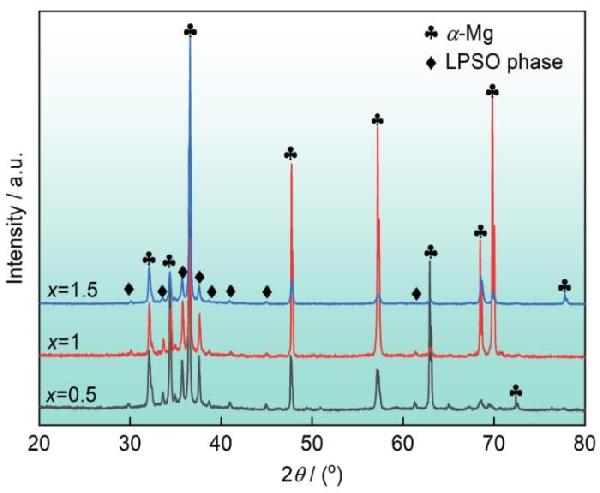

> 含LPSO相Mg-Y-Er-Ni合金的組織和拉伸性能

893

編輯:中冶有色技術(shù)網(wǎng)

來源:歐陽康昕,周達(dá),楊宇帆,張磊

893

編輯:中冶有色技術(shù)網(wǎng)

來源:歐陽康昕,周達(dá),楊宇帆,張磊

| Alloys | Mg | Y | Er | Ni |

|---|---|---|---|---|

|

Mg97Y1.5Er0.5Ni1 Mg97Y1Er1Ni1 Mg97Y0.5Er1.5Ni1 |

Bal. Bal. Bal. |

5.04 3.42 1.78 |

3.11 6.43 9.47 |

2.29 2.11 2.31 |

| Position | Mg | Y | Er | Ni |

|---|---|---|---|---|

|

A B C |

90.69 90.64 90.68 |

3.62 2.36 0.94 |

1.22 2.94 3.72 |

4.47 4.56 4.66 |

| Position | Mg | Y | Er | Ni |

|---|---|---|---|---|

|

A B C D |

89.48 98.14 89.91 90.39 |

3.86 0.71 2.48 1.32 |

1.48 1.15 2.79 3.51 |

5.18 - 4.62 4.78 |

| Alloys |

RE/%, atomic fraction |

UTS / MPa | YS / MPa | Elongationg / % | State |

|---|---|---|---|---|---|

|

Mg97Y1Er1Ni1 Mg97Y1Er1Ni1 Mg96.23Zn0.88Dy2.21Er0.68[26] Mg96.23Zn0.88Dy2.21Er0.68[26] Mg97.5Zn0.9Y0.8Gd0.8[13] Mg97.5Zn0.9Y0.8Gd0.8[13] Mg98.5Y1Ni0.5[17] Mg97Gd2Ni1[16] |

2 2 2.89 2.89 1.6 1.6 1 2 |

223 229 150.51 123.29 228.8 210.2 208 203 |

124 128 84.36 95.79 149 104.6 93 - |

8.0 8.1 6.74 7.03 3.2 7.8 8.0 8.8 |

As-cast T4 As-cast T4 As-cast T4 As-cast As-cast |

分享 0

分享 0

舉報 0

舉報 0

收藏 0

收藏 0

反對 0

反對 0

點贊 0

點贊 0

中冶有色技術(shù)平臺

中冶有色技術(shù)平臺 2024年12月27日 ~ 29日

2024年12月27日 ~ 29日  2024年12月27日 ~ 29日

2024年12月27日 ~ 29日  2025年01月03日 ~ 05日

2025年01月03日 ~ 05日  2025年01月03日 ~ 05日

2025年01月03日 ~ 05日  2025年01月03日 ~ 05日

2025年01月03日 ~ 05日